Emkhakheni wemishini yezimboni kanye nemishini, ukusebenza kahle kwama-valve kubalulekile ukuze kuqinisekiswe ukusebenza kahle kwezinqubo ezihlukahlukene.Ama-gearbox ama-valve adlala indima ebalulekile kulokhu, ahlinzeka nge-torque edingekayo nokulawula ukusebenza kwe-valve ezinhlelweni ezihlukene.Ukusuka kuwoyela negesi kuya ekwelashweni kwamanzi, ukuguquguquka kwamabhokisi kagiya wama-valve kuwenza abe yingxenye ebaluleke kakhulu ezimbonini eziningi.

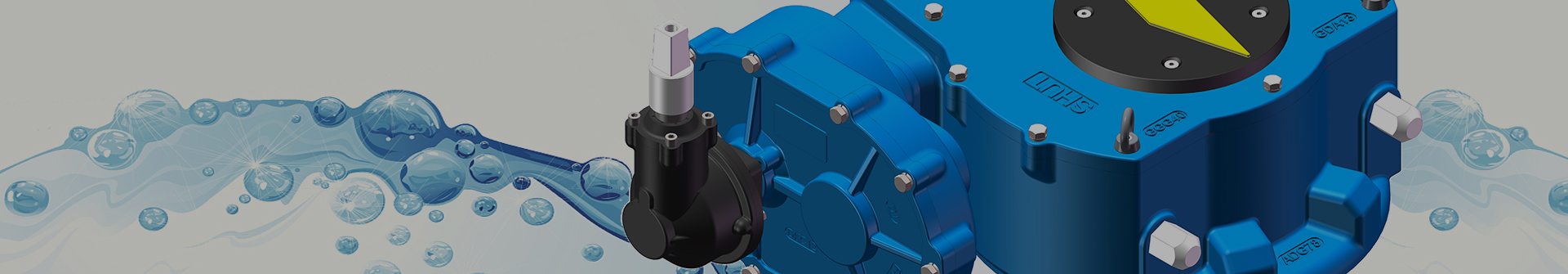

Enye yezinto ezibalulekile ekusetshenzisweni okusabalele kwama-valve gearbox amandla awo okuphatha izinhlobo ezahlukene zama-valve.Kungakhathaliseki ukuthi uvemvane, ibhola, isango noma ama-valve embulunga, lawa ma-gearbox aklanyelwe ukuthwala izinhlobo ezihlukahlukene zama-valve, awenze afanelekele izindawo ezihlukene zezimboni.Lokhu kuvumelana nezimo kuvumela ukuhlanganiswa okungenamthungo ezinhlelweni ezihlukene, ukuhlinzeka ngokusebenza okuthembekile, okusebenzayo kwe-valve ezinhlelweni ezihlukahlukene.

Embonini kawoyela negesi, ama-gearbox e-valve asetshenziswa ezinqubweni ezibucayi ezifana nokusebenza kwamapayipi, ukusebenza kokucwenga kanye nokubhola ogwini.Lawa ma-gearbox enzelwe ukumelana nezimo zemvelo ezinzima, izingcindezi eziphezulu namazinga okushisa aphakeme, ukuqinisekisa ukusebenza okuthembekile kwe-valve ekufakweni kwesidingo sikawoyela negesi.Ukuthi alawula ukugeleza kukawoyela ongahluziwe noma alawula ingcindezi yegesi yemvelo, amabhokisi egiya ama-valve adlala indima ebalulekile ekugcineni ubuqotho nokusebenza kahle kwale misebenzi.

Ekulapheni kwamanzi namanzi angcolile, amabhokisi egiya ama-valve asiza ukuphatha ukugeleza kwamanzi, amakhemikhali nolunye uketshezi ezindaweni zokwelashwa.Ukusuka ekulawuleni ukunyakaza kodaka kuye ekulawuleni ukugeleza kwamanzi ahlanzekile, lawa mabhokisi kagiya abalulekile ekugcineni izinqubo zokuhlanza amanzi zisebenza kahle futhi zisebenza kahle.Ikhono lazo lokusingatha izinto ezonakalisayo nokusebenza ezindaweni eziyinselele lizenza zifanelekele izidingo eziqinile zokusetshenziswa kokuhlanza amanzi namanzi angcolile.

Imboni yokuphehla amandla iphinde ithembele kumagiya ama-valve ukuze kube lula ukusebenza kwama-valve ezitshalo zamandla, ukuqinisekisa ukukhiqizwa nokusatshalaliswa kukagesi ngempumelelo.Ukuthi ulawula ukugeleza kwesitimu ohlelweni lukabhayela noma ulawula ukugeleza kwamanzi apholisayo, lawa ma-gearbox abalulekile ekusebenzeni okuphephile nokuthembekile kwezindawo zokuphehla amandla.Ukwakhiwa kwawo okumazombezombe namandla okulawula anembe awenza abaluleke kakhulu ekugcineni ukusebenza kahle kwama-valve ezinhlelweni zokuphehla amandla.

Ngaphezu kwalezi zimboni, ama-gearbox e-valve abuye asetshenziswe ekucubunguleni amakhemikhali, kwezemithi, ekukhiqizeni ukudla neziphuzo, njll. Ukusebenzisana kwazo okuhlukahlukene nokuthembeka kuwenza afanelekele izinqubo ezahlukahlukene, lapho ukulawulwa okunembile kwama-valve kubalulekile ekugcineni ukusebenza kahle nomkhiqizo. izinga.

Ngaphezu kwalokho, intuthuko kubuchwepheshe be-valve gearbox yenze ukuthi kuthuthukiswe izixazululo ezisebenza kahle nezihlakaniphe kakhudlwana.Ama-gearbox esimanje ama-valve anikeza ukusebenza okuthuthukisiwe nokuthembeka anezici ezinjengokuqapha okukude, ukugcinwa kokuqagela kanye nezinhlelo zokulawula ezididiyelwe.Lezi zindlela ezintsha zobuchwepheshe azithuthukisi kuphela ukusebenza kahle kwama-valve, kodwa futhi zifaka isandla ekuthuthukisweni okuphelele kwesistimu ezinhlelweni ezihlukahlukene zezimboni.

Kafushane, izinhlelo zokusebenza ze-valve gearbox zibanzi futhi zihlukahlukene, zithatha izimboni nezinqubo eziningi.Ukuzivumelanisa nezimo, ukwethembeka kanye nokuthuthuka kwezobuchwepheshe kubenza babe izingxenye ezibalulekile zokuqinisekisa ukusebenza kahle kwama-valve emisebenzini ehlukahlukene.Njengoba imboni iqhubeka nokuvela futhi idinga amazinga aphezulu okusebenza nokulawula, amabhokisi egiya ama-valve ahlala ebalulekile ukuze ahlangabezane nalezi zidingo ezishintshayo kanye nokwandisa ukusebenza kahle.

Isikhathi sokuthumela: Jul-27-2024